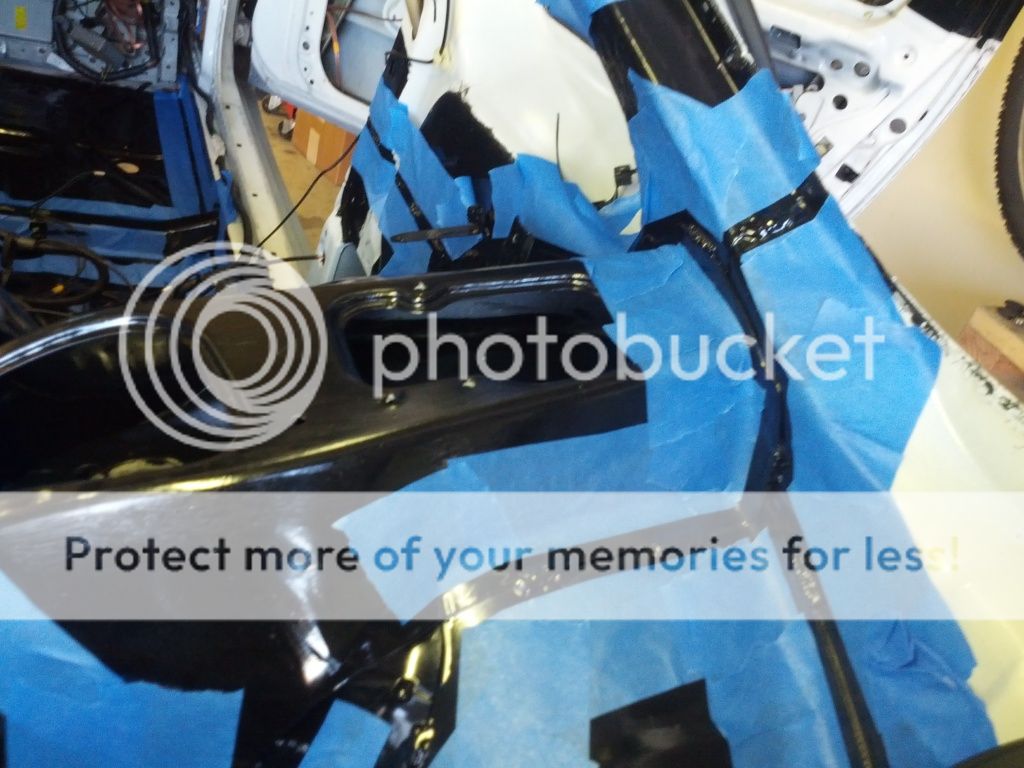

| I've been working away on seam welding my Z. It's been a **relatively** affordable project for me to undertake while I build a new house. Besides the costs of the welder(s) and the rotisserie, everything else has been pretty low-cost. This all started because the under-body protection under my car was in poor condition. You could literally run your nails across it and it would fall off in your hand. Fortunately, the metal under the coating was still in good shape. I removed all the under-body coating with a few wire wheels on an angle grinder as well as my air powered rotary tool. I probably spent about $50-60 on wire wheels and wire cups at northern tool over the last couple months. It was a time consuming process and sand blasting would have likely been faster, but being a renter I had limited options for making a mess in the garage/driveway. I should apologize for my lack of welding pictures, I swear I had taken some, but I can't find them now. Anyway, here's what I do have: My welding inside and outside is mostly complete. I'll still need to pull my dash to do the firewall and by the petals. I also have plans to add a re-enforced casing to the frame rails which are easily bent when jacking up the car. I have washed the interior with KBS Aqua Klean and etched the interior with KBS Rust Blast and am applying some KBS Rust Seal to ensure the metal doesn't rust. Blurry pic of my interior welds

Just beginning to apply the rust seal

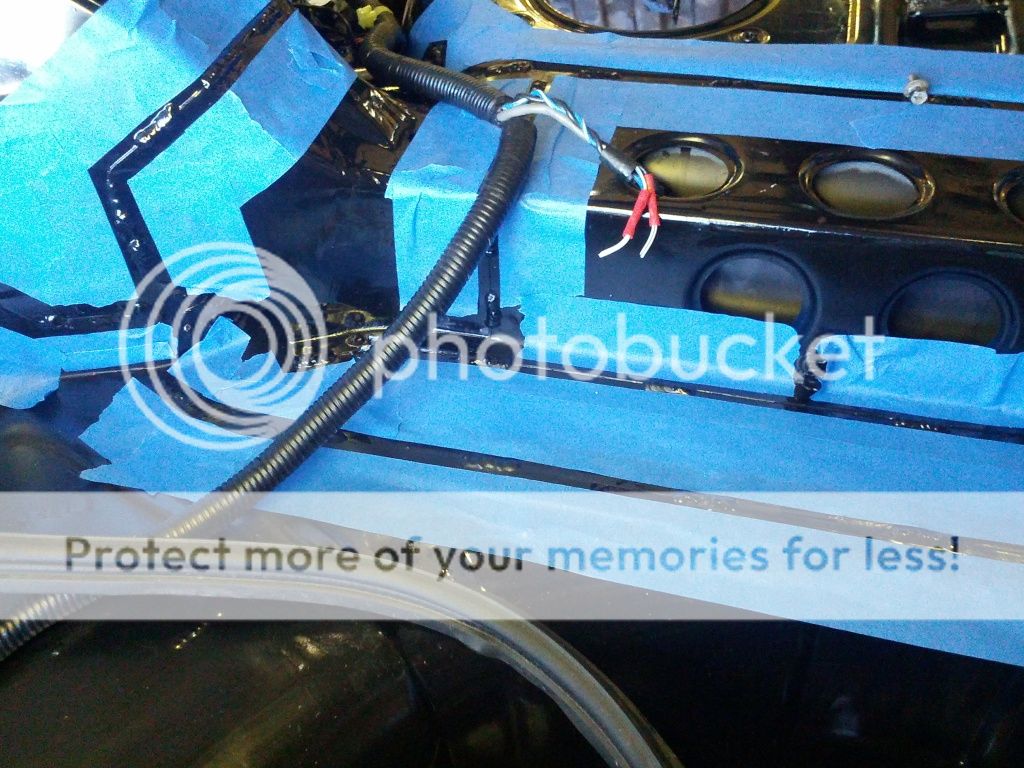

You can see my welds here, I was going for 1 inch of weld followed by 3 inches of space. Some areas required the welds to be a bit closer.

Once the metal was protected I masked it off to prepare it for seam sealer. I had read many different posts from all around the intertubes in regards to what order to do this stuff (paint, prime, seal, etc.) and there didn't seem to be any specific conclusions. Everyone did it differently and it all worked out fine. I'm keeping it simple and sealing right on top of the rust seal. I limited the first application to a small area, let it dry, and was pleased to see that it adhered to it quite well.

I plan to have the rest of the interior sealed this weekend and next week I'll start prepping the bottom of the car to go through the same steps. I'll be sure to take more pictures of the welded bare metal before I start coating it. I'll be finishing off the interior and under-body with a spray on coat of second skin spectrum to help cut down on road noise, but that'll probably be a little ways off yet. I've also been told that it's acceptable to add an additional coat of a truck-bed liner product in addition to the spectrum if I'm concerned about the protective qualities of the product.

|